CRYO SCIENTIFIC EQUIPMENT

At Apollo Heat Exchangers, our Cryogenic vertical specializes in the design and manuf acturing of advanced aluminium plate fin heat exchangers tailored for cryogenic applications. With a focus on innovation and efficiency, we provide state-of-the-art solutions for gas liquefaction processes, ensuring optimal performance in extreme temperatures.

Our expertise extends to the development of comprehensive cryogenic cold boxes, engineered to meet the rigorous demands of the industry. Committed to quality and precision, Apollo delivers reliable products that enhance operational efficiency and support the adv ancement of cryogenic technologies.

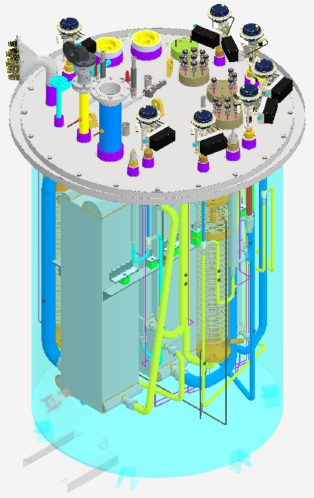

Cryogenic Helium Cold Box

Apollo has designed & manufactured Helium Liquefier with the help of B ARC Cryo Technology Division, Mumbai. It converts gaseous helium to liquid helium by cryogenic cooling process. The Helium Liquefier is designed f or 100 Litre / hour Liquification capacity.

The main components of Helium Liquefier ar e as below:

- Cold Box Vessel

- Aluminium Brazed Plate Fin Heat Exchangers – 6 No

- Activated Charcoal Adsorber Beds – 3 No

- SS Inter connecting Pipe with JT Valves

- Cryogenics Turboexpanders – 2 No

- Cryogenic Long Stem Bellow-Sealed Control Valves – 6 No

- Temperature Sensors

- Pressure Transmitters

All the cryogenic equipment with interconnected piping and instrumentation (Coldbox

assembly) are housed inside a v acuum vessel and supported on the top cover with

spring hangers under super insulated & Vacuum condition of 10^-7 mbar.

Specification: Liquid Helium P lant

1 Capacity: 100 Litre / Hr

2 Size: Dia 2.0 m x 3.0 m Height

2 160 Mtr of Weld Length

3 100% Al Heat Exchanger & SS Pipe line

4 Joining Processes used Vacuum Brazing &

TIG Welding

4 Temperature range: 300 K to < 4 K

If you need more details about Transformer Oil Cooler and Convertor Cooler for WAG-7 & WAG-9 locomotives, contact us at sales@apollohx.com We can select the right product for your application.