CRYO SCIENTIFIC EQUIPMENT

Cryogenic Aluminium Plate Fin Heat Exchanger

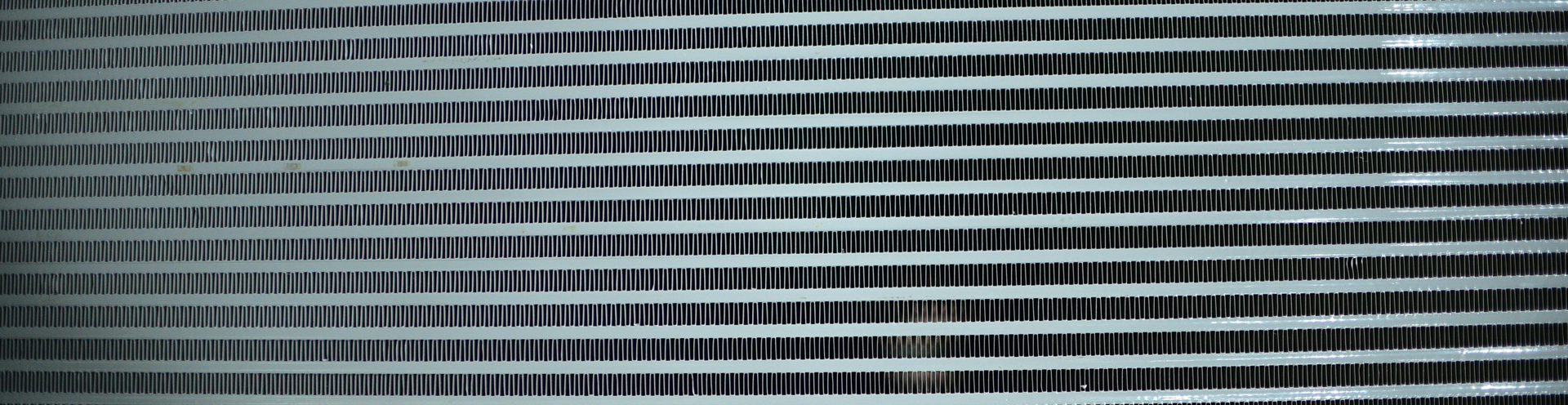

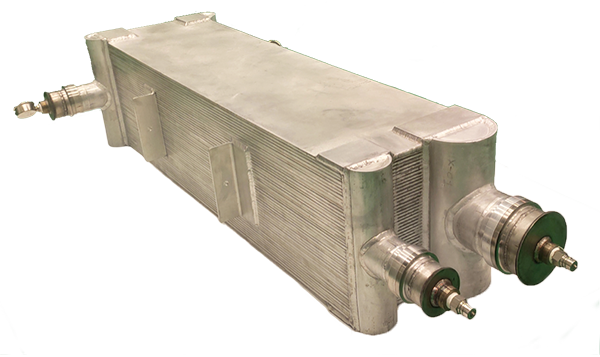

Apollo designs and manufactures specialized Cryogenic Aluminium Plate Fin Heat Exchangers for helium and hydrogen cooling. These brazed aluminium plate fin heat exchangers (BAHX) made by fluxless vacuum brazing & designed as per customer requirements.

Precise thermal design and fin sel ection is done to ensure achieve this cooling performance is delivered. The counter flow heat exchanger design ensures the cooling from both streams of gas is optimized for heat transfer and minimal pressure drop. The cryogenic plate fin heat exhangers can be supplied with a a luminium to SS bimetallic joint as an additional optional accessory.

Salient Features of compact aluminium heat exchangers:

- Manufactured via fluxless vacuum brazing process to ensure clean brazing joints and high burst strength of more than 80 bar.

- Effectiveness > 95 %

- Maximum heat transfer area in less area thus requires lesser foot print area.

- Long life aluminium alloy ensures trouble free performance for over 20+ years

- Designed to meet ALPEMA Standards and ASME Sec VIII Div 2

Specification:

1 Heat Load: Helium Gas – up to 1000 W (Refrigeration Mode)

2 Working pressure: Max 80 bar

3 Vacuum Brazed Bar & Plate Design

4 MSLD Leak testing up to leak rate of 10^-07 mbar