Diesel Locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover is a diesel engine. Several types of diesel locomotive have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels (drivers).

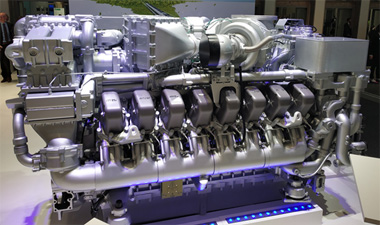

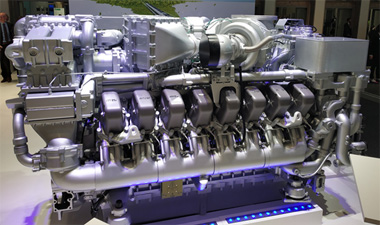

Diesel Engine

This is the main power source for the locomotive. It comprises a large cylinder block, with the cylinders arranged in a straight line or in a V. The engine rotates the drive shaft at up to 1,000 rpm and this drives the various items needed to power the locomotive. As the transmission is normally electric, the engine is used as the power source for the alternator that produces the electrical energy to drive the locomotive.

Fuel Injection

Ignition in a diesel engine is achieved by compressing air inside a cylinder until it gets very hot (say 400°C, almost

800°F) and then injecting a fine spray of fuel oil to cause a miniature explosion. The explosion forces down the piston

in the cylinder and this turns the crankshaft. To get the fine spray needed for successful ignition the fuel has to be

pumped into the cylinder at high pressure. The fuel pump is operated by a cam driven off the engine. The fuel is

pumped into an injector, which gives the fine spray of fuel required in the cylinder for combustion.

Since 40 years, Apollo has been an approved supplier to Indian Railways for precision engine components of diesel

locomotive like MAK Locomotive, Alco Locomotive and GM Locomotive.

Apollo is RDSO approved Indian Railway supplier to DLW, DMW and other zonal railways in India.

With a rich technical expertise for pipe bending and tube drawing, Apollo Industrial Corporation has developed diesel

locomotive components like fuel injection tube, fuel oil line, lube oil line, nozzle cooling sleeve, crankcase tubing kit

and others to one of the largest railway network.

Apollo has been the first company in India t o locally indigenize the imported diesel locomotive components.

Turbo Charging

The amount of power obtained from a cylinder in a diesel engine depends on how much fuel can be burnt in it.Turbo

charging is used to increase the amount of air pushed into each cylinder. The turbocharger is driven by exhaust gas

from the engine. This gas drives a fan which, in turn, drives a small compressor which pushes the additional air into the

cylinder. Turbocharging gives a 50% increase in engine power.

Air Cooled Charge Air Cooler developed for ALCO Locomotive for Indian Railways was the first product of Apollo

Industrial Corporation in aluminum plate and fin type heat exchange design. Apollo has supplied more 1200 Nos of the

Charge Air Coolers for diesel locomotive. We are pioneer to develop and manufacture first import substitution

indigenous charge air cooler for indian railway diesel locomotive.

Air Cooled Charge Air Cooler developed for ALCO Locomotive for Indian Railways was the first product of Apollo

Industrial Corporation in aluminum plate and fin type heat exchange design. Apollo has supplied more 1200 Nos of the

Charge Air Coolers for diesel locomotive. We are pioneer to develop and manufacture first import substitution

indigenous charge air cooler for indian railway diesel locomotive.

When you need your engine to perform at optimum conditions,

our air cooled aluminum radiator made by vacuum brazing

process with perfectly selected fins will ensure that you get the

most effective cooling.

View More

Do you want to develop new diesel engine components?

With a core technical expertise in pipe bending & making assemblies for critical

applications, Apollo has developed many such assemblies for diesel locomotive

of fitted with GM, ALCO & MAK engines. Apollo has been the leading company in

India to manufacture and test critical diesel engine components and tube/pipe

assemblies. For your requirements of such items in bulk kindly get in touch.

Discuss your project with us!

At Apollo we understand that while the basic concept of cooling is fairly

straightforward, there are areas of theory and execution where even the most

veteran engineer could use their best of knowledge to create the cooling

system for their application. Technical, Design and Engineering Support is your

open line of communication to our engineering team.